Glass Perfume Bottles, Empty Spray Perfume Bottles Manufacturers

HJ Glass Factory

We are a professional

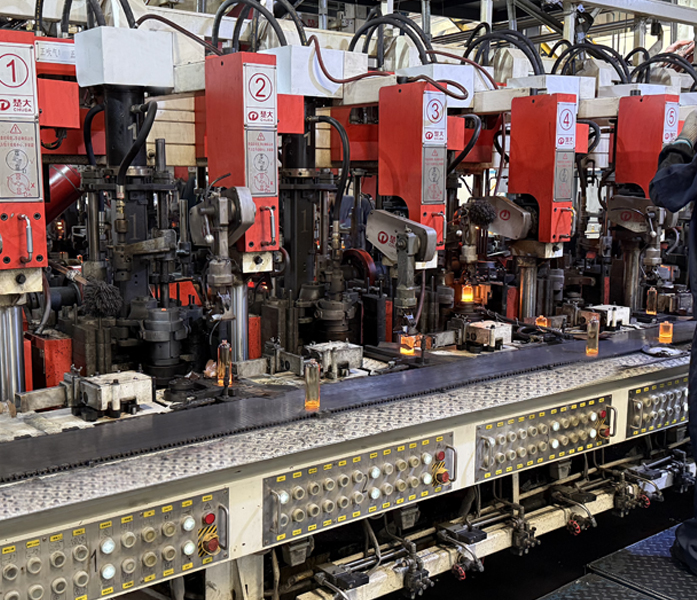

China Empty Glass Perfume Bottles Manufacturers and Wholesale Empty Spray Perfume Bottles Factory, with strong development and supporting service capabilities. At present, the daily output of the factory can reach 1.4 million glass bottles and 1 million bottle caps, supporting mold customization, accessory development, and multiple post-processing processes such as spraying, printing, electroplating, hot stamping, etc.

We offer a wide range of cover material options, including ABS, PP, Surlyn, K-resin, PCTA, PE, and acrylic, to meet the texture and functional needs of different brands.

Over the years, we have earned the trust and praise of numerous customers. We continue to introduce advanced equipment, improve manufacturing accuracy, pay attention to market changes, optimize products and services, and only bring higher standard packaging solutions to customers.

-

In the competitive landscape of the fragrance industry, the integrity of packaging is paramount, particularly when navigating the complexities of global logistics. An Empty Perfume Bottle is not merely a vessel for liquid; it is a sophisticated engineered barrier designed to withstand variations in ...READ MORE

-

In the competitive landscape of home fragrance, the technical design of a container is just as critical as the olfactive profile of the scent itself. For engineers and B2B procurement managers, selecting Reed Diffuser Glass Bottles is not merely an aesthetic choice but a calculation of fluid dynamic...READ MORE

-

In the competitive aromatherapy market, the efficacy of a reed diffuser is determined not just by the quality of the essential oil blend, but by the engineering of the packaging. For wholesalers and private label brands, the selection of Empty Glass Diffuser Bottles is a critical decision that impac...READ MORE

The Manufacturing Process of High-Quality Glass Perfume Bottles

Introduction to Glass Perfume Bottle Manufacturing

High-quality glass perfume bottles are essential not only for preserving fragrance but also for enhancing brand image. HJ Glass Factory is a professional manufacturer specializing in the production of perfume bottles, fragrance bottles, and bottle caps, offering strong development and supporting service capabilities.

Step 1: Raw Material Selection

The first step in manufacturing glass perfume bottles involves selecting high-grade raw materials, such as silica sand, soda ash, and limestone. The purity and quality of these materials directly affect the clarity, strength, and overall appearance of the bottles.

Step 2: Glass Melting and Forming

- Melting: Raw materials are melted in high-temperature furnaces to form molten glass.

- Forming: The molten glass is then shaped into bottles through various techniques, including blow molding and press molding, to achieve precise dimensions and desired designs.

Step 3: Mold Customization

HJ Glass Factory supports mold customization to meet the unique design requirements of different brands. Customized molds allow for intricate bottle shapes, logo embossing, and other specialized features.

Step 4: Surface Treatments and Decoration

- Spraying: Provides color and surface texture options.

- Printing: Enables brand logos and decorative patterns.

- Electroplating and Hot Stamping: Adds metallic finishes and luxury effects.

Step 5: Cap and Accessory Development

HJ Glass Factory offers a wide range of cover material options, including ABS, PP, Surlyn, K-resin, PCTA, PE, and acrylic, to satisfy both aesthetic and functional needs of perfume brands. Accessory development ensures that each bottle is complete and ready for the market.

Step 6: Quality Control and Packaging

- Inspection: Each bottle undergoes rigorous quality checks for clarity, thickness, and defect-free surfaces.

- Packaging: Bottles are carefully packed to prevent damage during transportation.

HJ Glass Factory's Commitment

Over the years, HJ Glass Factory has earned the trust and praise of numerous customers. The company continues to introduce advanced equipment, improve manufacturing accuracy, stay updated with market trends, and optimize products and services to provide high-standard packaging solutions for perfume brands.

How to Choose the Right Glass Perfume Spray Bottles for Your Fragrance Brand

Introduction

Choosing the right glass perfume spray bottles is crucial for any fragrance brand. The bottle not only protects the perfume but also represents the brand's image and quality. With numerous options available, selecting the perfect bottle requires understanding the materials, design, functionality, and customization options.

Consider the Material of the Bottle

The material of the perfume bottle affects its durability, appearance, and user experience. HJ Glass Factory specializes in high-quality glass bottles suitable for various fragrances.

- Glass Types: Clear, frosted, colored, or customized glass can convey different brand aesthetics.

- Durability: Thick and high-grade glass ensures long-term protection of perfume contents.

- Environmental Impact: Glass is reusable and recyclable, appealing to eco-conscious consumers.

Choose the Right Spray Mechanism

The spray mechanism affects the fragrance application and customer experience. Consider the following:

- Spray Precision: A consistent and fine mist enhances the perception of quality.

- Compatibility: Ensure the pump matches the bottle neck and fragrance viscosity.

- Durability: High-quality pumps prevent leakage and maintain long-term functionality.

Select the Appropriate Cap Material

HJ Glass Factory offers a wide range of cover material options to meet different brand needs:

- ABS, PP, Surlyn, K-resin, PCTA, PE, Acrylic: These materials provide various textures, finishes, and durability levels.

- Design Flexibility: Custom caps can include unique shapes, prints, or metal accents to enhance brand identity.

Customization and Post-Processing Options

Customization allows your perfume bottles to stand out in a competitive market. HJ Glass Factory supports multiple post-processing methods:

- Spraying: Colorful or metallic finishes to match brand themes.

- Printing: Logo or pattern printing to enhance brand recognition.

- Electroplating & Hot Stamping: Premium metallic effects for luxury fragrances.

Consider Production Capacity and Reliability

Reliable supply is key for fragrance brands. HJ Glass Factory offers:

- Daily Output: 1.4 million glass bottles and 1 million bottle caps.

- Custom Mold Support: Enables unique bottle designs without compromising production speed.

- Quality Assurance: Advanced equipment and precise manufacturing ensure consistent product quality.

Conclusion

Selecting the right glass perfume spray bottles involves evaluating material quality, spray mechanism, cap options, customization, and manufacturer reliability. By choosing a trusted partner like HJ Glass Factory, fragrance brands can ensure high-quality packaging that reflects their identity and meets customer expectations.

English

English Español

Español