50ml Perfume Bottle, Empty Perfume Bottles 50ml Manufacturers

Explore our versatile 50ml perfume bottles, designed for those who appreciate a balance between functionality and style.

HJ Glass Factory

We are a professional

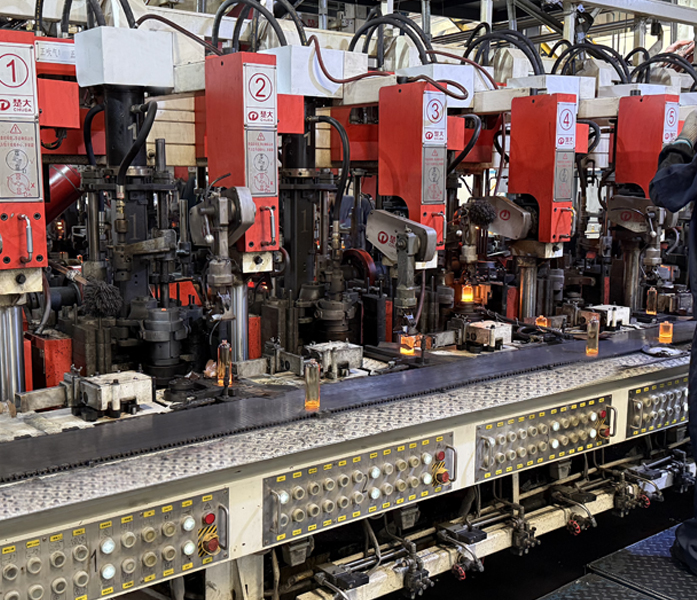

China Empty 50ml Perfume Bottle Manufacturers and Wholesale Empty Perfume Bottles 50ml Factory, with strong development and supporting service capabilities. At present, the daily output of the factory can reach 1.4 million glass bottles and 1 million bottle caps, supporting mold customization, accessory development, and multiple post-processing processes such as spraying, printing, electroplating, hot stamping, etc.

We offer a wide range of cover material options, including ABS, PP, Surlyn, K-resin, PCTA, PE, and acrylic, to meet the texture and functional needs of different brands.

Over the years, we have earned the trust and praise of numerous customers. We continue to introduce advanced equipment, improve manufacturing accuracy, pay attention to market changes, optimize products and services, and only bring higher standard packaging solutions to customers.

-

In the competitive landscape of the fragrance industry, the integrity of packaging is paramount, particularly when navigating the complexities of global logistics. An Empty Perfume Bottle is not merely a vessel for liquid; it is a sophisticated engineered barrier designed to withstand variations in ...READ MORE

-

In the competitive landscape of home fragrance, the technical design of a container is just as critical as the olfactive profile of the scent itself. For engineers and B2B procurement managers, selecting Reed Diffuser Glass Bottles is not merely an aesthetic choice but a calculation of fluid dynamic...READ MORE

-

In the competitive aromatherapy market, the efficacy of a reed diffuser is determined not just by the quality of the essential oil blend, but by the engineering of the packaging. For wholesalers and private label brands, the selection of Empty Glass Diffuser Bottles is a critical decision that impac...READ MORE

How to Choose the Right 50ml Perfume Bottle for Your Brand

Understanding Your Brand's Identity

Before selecting a 50ml perfume bottle, it is crucial to understand your brand's positioning and target audience. A perfume bottle is not just a container; it reflects the brand's image, luxury level, and style.

Consider Bottle Material and Quality

At HJ Glass Factory, we specialize in producing high-quality perfume bottles, fragrance bottles, and bottle caps. We offer various materials that cater to different brand needs:

- Glass: Classic and premium feel, ideal for luxury scents

- Plastic options: ABS, PP, Surlyn, K-resin, PCTA, PE, and acrylic for lightweight and functional designs

Choosing the right material ensures the bottle aligns with your brand's tactile and visual expectations.

Design and Customization Options

Customization is essential to differentiate your brand. HJ Glass Factory supports:

- Mold customization for unique bottle shapes

- Accessory development including caps and closures

- Post-processing techniques such as spraying, printing, electroplating, and hot stamping

These options allow brands to create distinctive packaging that enhances product appeal and shelf presence.

Functionality and User Experience

A perfume bottle should be functional and easy to use while maintaining an elegant look. Consider aspects such as:

- Spray mechanism quality

- Ergonomics of the bottle and cap

- Durability of materials to prevent breakage or leakage

Production Capacity and Supply Reliability

HJ Glass Factory has a daily production capacity of 1.4 million glass bottles and 1 million bottle caps, ensuring timely supply for bulk orders. Their commitment to advanced equipment and precise manufacturing guarantees consistent quality, helping brands maintain a reliable supply chain.

Conclusion

Selecting the right 50ml perfume bottle for your brand involves a balance of aesthetics, functionality, and material quality. By partnering with an experienced manufacturer like HJ Glass Factory, you can access customized designs, high-quality materials, and a reliable production process, ensuring your perfume stands out in the market.

The Manufacturing Process Behind Empty Perfume Bottles 50ml

Introduction

Empty perfume bottles of 50ml are widely used in the fragrance industry due to their convenient size and elegant design. The production of these bottles requires precision, advanced materials, and multiple post-processing techniques to meet the aesthetic and functional demands of different brands. HJ Glass Factory specializes in manufacturing high-quality perfume bottles, fragrance bottles, and bottle caps, providing comprehensive support from mold customization to accessory development.

Step 1: Glass Bottle Production

Raw Material Selection

The production starts with selecting high-quality glass materials that ensure clarity, durability, and safety for perfume storage.

Forming Process

Glass bottles are formed using advanced molding techniques. HJ Glass Factory supports custom mold development to create unique bottle shapes and designs. The daily output can reach 1.4 million glass bottles, ensuring large-scale production capacity.

Quality Inspection

Each bottle undergoes strict quality checks to ensure uniform thickness, smooth surfaces, and absence of defects.

Step 2: Post-Processing Techniques

After molding, the bottles are subjected to various finishing techniques to enhance their appearance and functionality:

- Spraying: Adds color or texture to the bottle surface.

- Printing: For brand logos, labels, or decorative designs.

- Electroplating: Creates metallic finishes on caps or bottle surfaces.

- Hot Stamping: Applies metallic foils or patterns for premium packaging.

Step 3: Cap Manufacturing

Caps are an essential part of perfume packaging, and HJ Glass Factory provides a wide range of materials to meet different brand needs, including: ABS, PP, Surlyn, K-resin, PCTA, PE, Acrylic

Caps are also processed using spraying, printing, and electroplating techniques to match the bottle design.

Step 4: Assembly and Packaging

After post-processing, the bottles and caps are carefully assembled and inspected for quality. HJ Glass Factory ensures that each unit meets the highest standards before packaging and delivery.

Step 5: Innovation and Customization

With continuous investment in advanced equipment and a focus on market trends, HJ Glass Factory offers:

- Customized molds for unique bottle designs

- Accessory development for caps and packaging

- Optimized post-processing techniques

- High-standard packaging solutions for different brands

Conclusion

The manufacturing of 50ml empty perfume bottles combines precision glass production, advanced post-processing, and high-quality cap assembly. HJ Glass Factory has established itself as a trusted supplier in the fragrance packaging industry, providing innovative, reliable, and customizable solutions for brands worldwide.

English

English Español

Español